All our cold rooms are made in our factory, designed by us; this is the only way we can make installations that are as our customers want them.

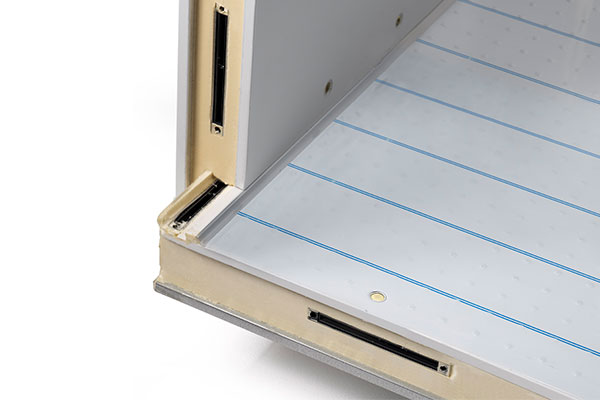

Cold rooms are a simple product in themselves: sheet metal, insulation, and a system of hooks to hold them together.

But it is only apparent simplicity, the coupling between the sheet metal and the insulation can be done in thousands of ways but only one is the right one, the best possible, which guarantees the best performance and the highest quality over time at a competitive price.

The profiles we currently use are the result of careful research that we have developed over time: maximum yield and production economy, indispensable to be competitive even in comparison with foreign production, made in countries where the cost of labor is lower.

Our cold rooms are completely made by us in Italy, in our factory in the province of Padua, the result of our experience and desire to do well.

We started from the design of the panel, rationalizing the shape to have it as beautiful as possible, we made the molds necessary for production: the cleaner the panel comes out, the fewer problems then there are in handling and assembly.

We designed new joints for the simplest and quickest assembly possible, so that the cold rooms could be fast assembled and perhaps disassembled and reassembled in the future, to be moved and adapted to new spaces.

Our product lines have been created to provide a concrete and targeted response to the specific needs of our customers.

This is not parochialism, in-house development and realization mean being able to offer customized and made-to-measure solutions: special projects that, starting from the customer's needs and idea, configure the best layout and characterize each element of our product.

MINICELLA

MINICELLA

SUPEREKO

SUPEREKO

SUPER10

SUPER10

MAXI

MAXI